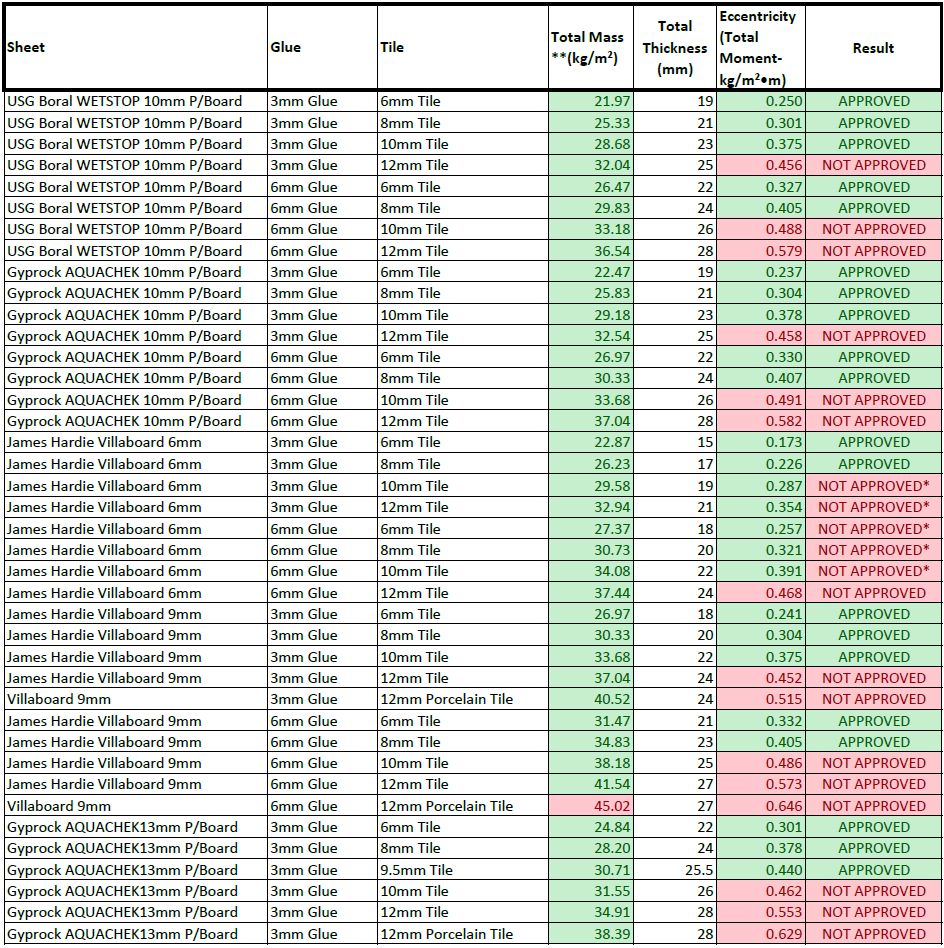

Triline Cavity Unit — Recommended Installation Combinations Table (GUIDE ONLY)

Points to Consider Before Applying Tiles

- See recommended chart for tile thickness & glue thickness loading to specific wallboard options. You must check that the tile loading does not exceed wallboard manufacturers recommendation for maximum loading weight of tiles and glue (weight will vary with glue thickness).

- Ensure the cavity slider wall frame is straight (they can get bent or bowed in transit). If the frame has bowed, straighten it before commencing tiling.

- For best results Triline recommends you clamp a straight edge to the cavity split jambs or on the tiled side to hold it straight while the tile glue dries. We also recommend packing in the throat of the cavity while the tile glue dries. If the cavity pocket is bowed when the glue dries it will stay bowed.

- If door has been fitted prior to tiling please remove door and store it according to the door manufacturer’s recommendations. The door may absorb moisture from tile glue if it is left in place. This may cause the door to bow and scrape against inside of cavity. For best results refit door when tile glue has dried.

QBCC published advice in March 2019 advising the unsuitability of some cavity sliders to support wall tiles. With this challenge raised, we wanted to ensure our cavity units were certified as compliant for your peace of mind.

Triline formulated an engineering test on our cavity slider unit to determine the capacity of the system to withstand loading from the application of wall tiles and associated wallboard and adhesives. Testing was completed on 24th March 2020 and the Cavity Unit was found to satisfy the prototype test requirements of AS1720.1 where timber moisture levels are maintained below 15%. Testing and reporting of results to the requirements ofAS1720.1 were carried out on a unit sized 2400H x 1200W to suit a 90mm frame.

For more information on wall combinations view our Engineering Brochure

FOR USE WITH THE FOLLOWING WALLBOARD TYPES:

- Gyprock Aquacheck

- USG Boral Wetstop

- James Hardie Villaboard